BAGGERS

FEATURES

- Efficient Servo Operation

- Minimize Labour

- Heat Sealing

- Soft Stop for Unstable Bottles

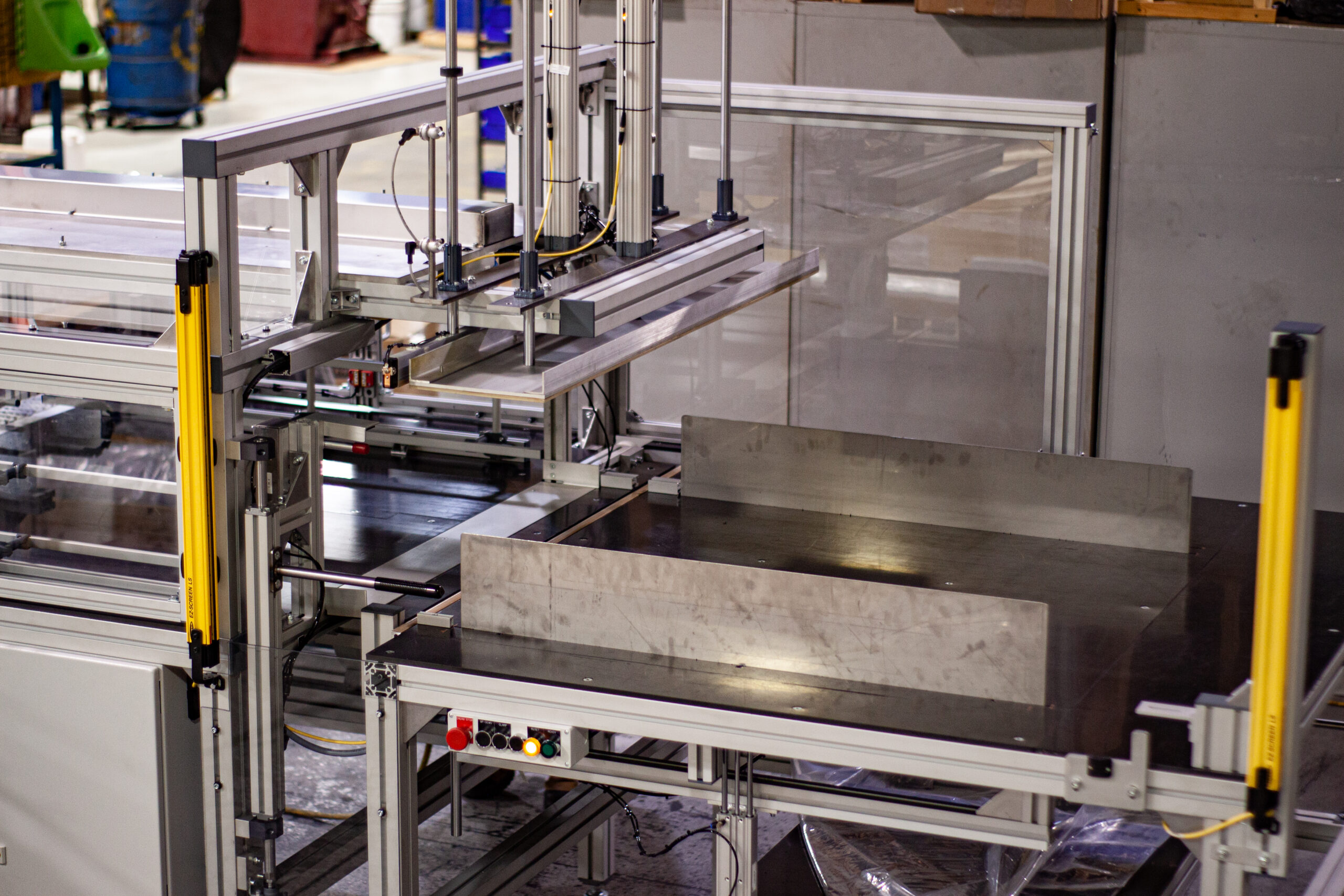

In 2014, K&G identified the inefficiencies and high maintenance requirements of baggers with pneumatic movements. In response, they pioneered the use of electric servos in baggers. This innovation allows a single device to index a row to a pattern and the pattern to the bag, enhancing efficiency and reducing maintenance needs.

K&G baggers are semi-automatic machines, requiring the operator to load the bag. They are available in two sizes:

Half Pallet Width: Supports speeds up to 3000bph*. Heat sealing is an optional feature on this model.

Full Pallet Width: This model features a swing-out arm for bag loading, eliminating the need for the operator to reach across the machine. It also includes heat sealing as a standard feature. This model can support speeds up to 6000bph*.

For handling unstable bottles, K&G baggers offer a unique soft stop capability. The row end stop moves when a bottle makes contact, cushioning it to the stopping position. This device also allows for staggered positioning and a saved point.

*Please note that the final cycle speed is dependent on the bottle type

Voltage: 220VAC 1 Phase

Current: 30A